Home > NEWS > Company News > Content

Hefei Zhongchen Beer, Beverage, Condiment Production Lines Have Witnessed High-speed Development of High-end Equipments at CBB 2014

Hits: Time:2013-10-23 08:27:00

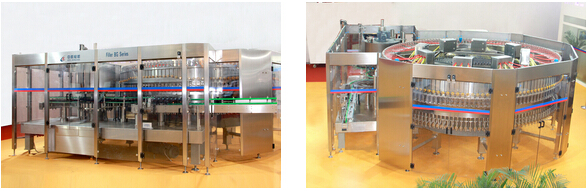

Hefei Zhongchen 50,000BPH high-speed pneumatic electro-filling valve beer glass filler & capper and 18,000CPH E-valve beer/beverage filler & seamer were exhibited this time.

50,000 BPH high-speed glass pneumatic electro-filling valve of beer filler & capper has been purchased by AB InBev because of its good performance. This machine has the following features in particular:

• Short tube high accuracy pneumatic electro-filling valve with double pre-evacuation; Adopt CO2 or nitrogen as counter pressure gas, no bottle no pre-evacuation & no fill.

• Streamline welded filler platform with sanitary bedplate; Burst bottles flusher; Filling bowl / control mechanism / crowner have auto elevating features.

• Suspension type main gear drive with VSD control; Sanitary bottle guiders, integrated bottle star wheels & open type bottle guiding plates; Centering devices with pre-centering by means of lifting guide poles with rollers; Side hanging bottle lifting cylinders.

Interior guiding sleeves of crowning heads adopt imported lubrication free material guiding sleeve; Crowning pressure compensation devices on bottle lifting pads.

• Equipped with imported high-pressure bubbler, bubbling with 85℃ hot sterilized water, and bubbling pressure is sync control with filler speed.

• Nashi brand vacuum pump with S.S water circulation tank features water temperature circulation controlling to guarantee vacuum degree≤-0.085Mpa.

• Circulation CIP of filler with dummy cups, and the channels are cleaned in sequence as per programs by means of open type valve-matrix / pipings station.

• Filling, burst bottles flushing, open&close of bowl gas vent tube, high-pressure bubbling, caps stirring, capping blow & feeding, display of cap lack, and machine lubrication, etc. are well auto-controlled via PLC & displayed in HMI; The machine speed is regulated as per bottle quantity signals from infeed / discharge conveyors, equipped with bottle infeed stopper, no bottle no filling & no capping, filling speed display & counter of filled bottles, etc.

18,000CPH E-valve beer/beverage filler & seamer also was exhibited, which won the favor from international beer / beverage giants, and it can specially meet production requirement on high-end canned beer / beverage of small and medium size beer / beverage plants. The electronic volumetric valve filling for can is the most advanced filling technology compared to traditional filling technology i.e. mechanical valve. Filling volume accuracy ±1.0ml (single valve test±0.5ml); Online adjustment of filling volume.

Filling system contains filling valve, filling bowl, liquid controller, height adjustment of filling bowl, etc. ; Central piping station & control includes liquid distributor, gas distributor, air control station, liquid feeding, CIP, etc.; Power of drive system and can conveyor is from the seamer is passed to the speed reducer, after the speed ratio is changed by the first sprocket drive. The gear on the reducer output shaft drives filling system and related parts. Can conveyor includes can feeding screw, can stopper, can feeding starwheel and baffles. Control system adopts the advanced electrical controlling units accurately control each filling station. Machine frame and protective door adopts toughened glass protective door, with various protection switches. Seamer adopts the high quality seaming heads well ensure seaming quality.

During the exhibition of four days, Hefei Zhongchen attracted a large number of professional visitors visit and inquire, by virtue of the above two sets of high quality equipment. The scene of customers waiting for the sales staff or technical staff to introduce the equipments was often. Customer recognition is our motivation. Hefei Zhongchen will work harder to continue to make its contribution for Chinese high-end production line equipments moving forward world's top level, such as beer, related alcohol, beverage and water, condiments, etc.

Mobile

Mobile Wechat

Wechat