Home > NEWS > Company News > Content

Hefei Zhongchen Craft Beer Production Line Sparkles in 2016

Craft beer which is a concept of tradition yet innovation constantly in beer brewage industry. All the description relating to beauty can be realized in craft beer: traditional material, delicate brewage, tiny production and graceful taste etc. In the modern society of fast advancement, craft beer is also in the pace of developing and innovation to cater for the increasingly improved appreciation from the mass.

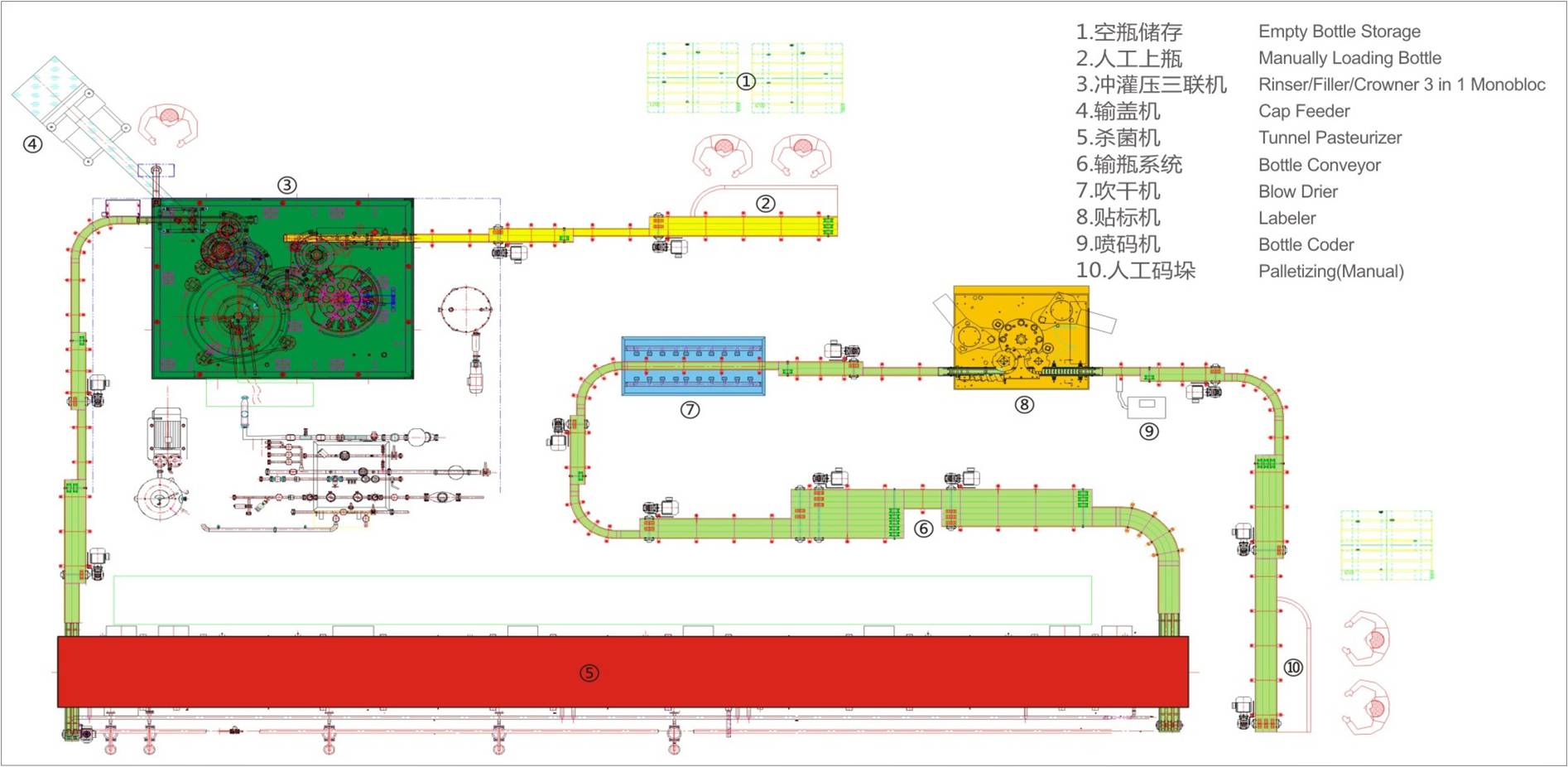

Following the step of the time, Zhongchen proactively faces every strict requirement and standard to make perfection more perfect in the research and development of the brewing equipment for craft beer.At the beginning of 2016, Zhongchen cooperated with AB InBev again which endowed Zhongchen with a new order on one craft beer filling and packaging production line with glass bottle.In recent years, Zhongchen has already integrated some newly-released and innovative projects for AB Inbev due to its advanced technology in design and manufacturing as well as considerate service,like production line with electronic valve For the combination of glass and PET bottles. Beer production line with plastickeg. 40000bph RGB beer line and 50000bph RGB draft beer production line had been delivered to AB Inbev Suqian branch successively and put into production smoothly.

In compliance with the strict request from AB Inbev on craft beer filling, Zhongchen supplied them with high-end equipment both with Zhongchen feature and international advanced technology. The Rinser-Filler-Capper 3 in 1 monobloc with multi-channel rinsing controlled by e-valve is equipped with twice-vacuumization system. CO2 is set as the back pressure in Filling tank in order to reduce the suction volume of O2 in filling bottles, and the volume of CO2 will be increased instead. And also ensure steady filling level, less beer loss and appropriate Oxygen-increase rate , which Is adaptable to fill the beer with high quality. The design of multi-channel rinsing controlled by e-valve will ensure the required cleanliness and residual water volume. It is also applied with pasteurization to control the PU precision, Which keeps the product with good taste and longer shelf life. Meanwhile, it is space-saving and with high line efficiency.

The chain-mesh newly-developed type pasteurizer is designed and manufactured combining the national situation and integrating the advanced technology both at home and abroad. Tunnel pasteurizer is specially designed for sterilization of bottle beer, which is manufactured with stainless steel all over the body. And driven by the reducer motor with high torque and low speed rotation, which guarantees running smoothly with low power consumption. The main body of the machine is adopted open-type wallboard structure, the top and two sides of the compartment are equipped with header and side door, which can make the machine observed, cleaned and maintained easily. All the spray pumps are imported With real time detection on outlet and pressure. The signal will be transferred to HIM. The spraying area is large and the sprout will not be stuck, furthermore, the spraying nozzles can be easily dismantled and cleaned. The heating water circular pipe system may fully make use of thermal energy which not only save the heat energy, but reduce the water consumption as well as the production cost.

The craft beer ask for extremely strict brewing skill, traditional material and even stricter requirement for filling and packing. Zhongchen absorbed the advanced technology.Both at home and abroad, making continuous innovation and breakthrough of quality to realize the qualitative leap in the field of production line for craft beer brewage. Zhongchen possesses rich manufacturing experience, the requirement for innovation and the pursuit for new technology. Zhongchen will continuously keep forging ahead with great advantage at the edge of the industry.

Mobile

Mobile Wechat

Wechat