PRODUCTS

Home > PRODUCTS > Beverage and Water Packaging L > Content

- Product Infomation

1. Water Treatment

Main Scope of Supply :Multi-media filter, activated carbon filter, softener, polishing filter, RO unit 1 or 2 pass, ultrafilter, chemical dosing device, ozoner, ultraviolet disinfection device, storage tanks, pumps and pipes, automatic control system, etc.

2. Processing and CIP

2. Processing and CIP

Mainly include following scope of supply:

1. Fruit crash/extrusion processing equipment, tea extraction equipment, etc.

2. Sugar dissolving equipment, mainly used to dissolve and filtrate the crystal sugar. The process can be selected as ambient temperature dissolving, or high temperature dissolving.

3. Blending equipment, used for batch preparing of beverages. Prepared beverages will enter the next process.

4. Homogenization, De-aeration, and Flash Pasteurization equipment mainly used to process tea, fruit juice, milk, etc.

5. Complete CIP system.

3. Factory Utilities Equipment

3. Factory Utilities Equipment

Mainly include:

1.Steam Supply System: Boiler room;

2.Refrigeration System: Ammonia chiller, glycol chiller, water chiller, cooling tower, etc.;

3.Compressed Air Supply System – HP / LP air compressors and air treatment equipment;

4.CO2 Generator and Purify System: Used to produce carbonated drinks with related CO2 generating / recovery, purification, storage, vaporization, and pressure reduction station, etc.;

5.Electricity Supply System: Including HV power distribution, LV power distribution, generators, whole plant cablings & wirings.

6.Piping System: Product piping and utility piping system.

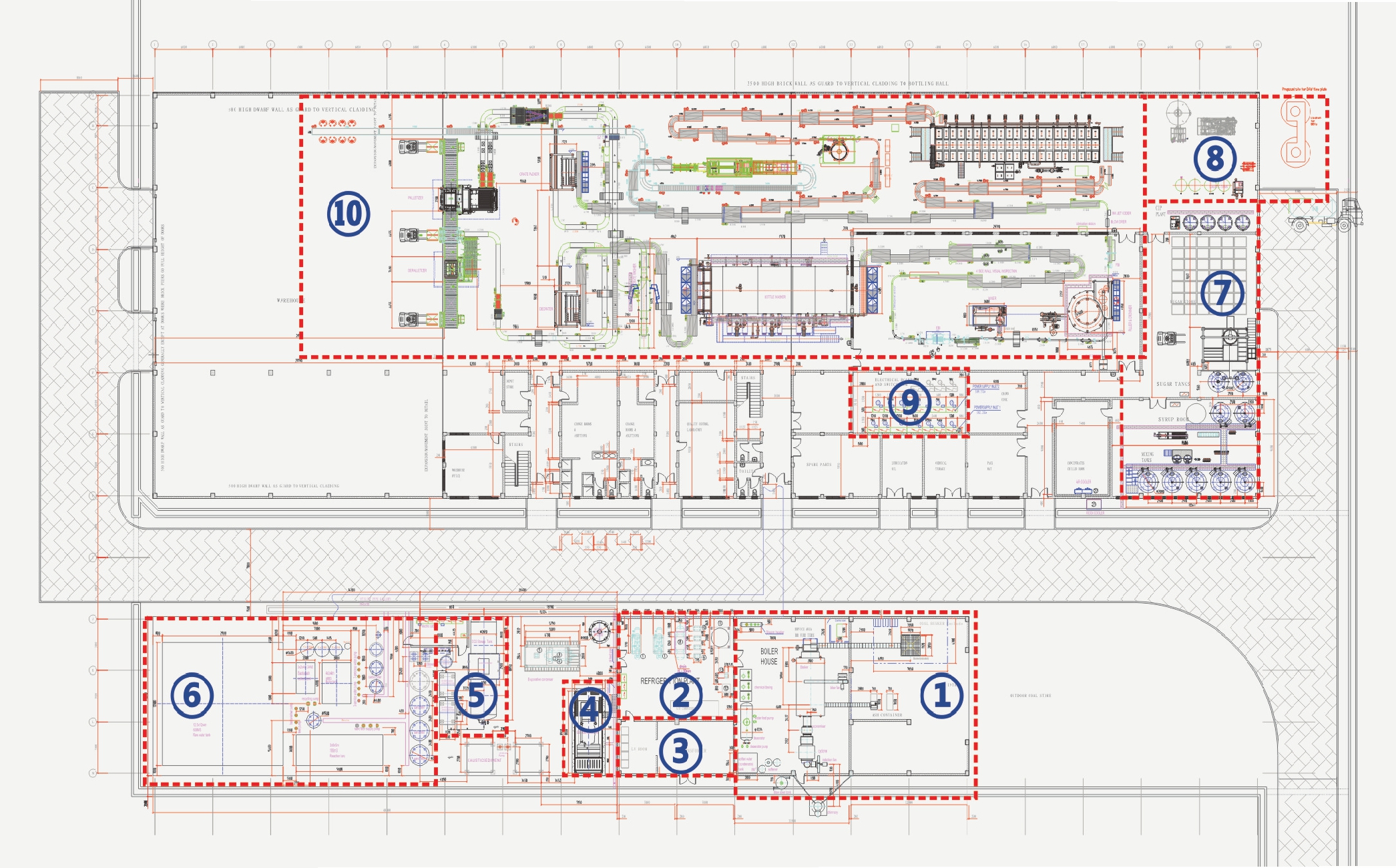

4. Demostration Layout

1.Boiler System

1.Boiler System

2.Refrigeration System

3.Air Compressor

3.Air Compressor

4.Generator

5. Co2 System

6. Water Treatment

7. Beverage Processing and CIP

8. Beer Processing

9. Central MCC Room

10. Beer & Beverage Combination Bottling Line

6. Water Treatment

7. Beverage Processing and CIP

8. Beer Processing

9. Central MCC Room

10. Beer & Beverage Combination Bottling Line

Mobile

Mobile Wechat

Wechat